INDUSTRIAL AI MONITORING & PREDICTIVE MAINTENANCE

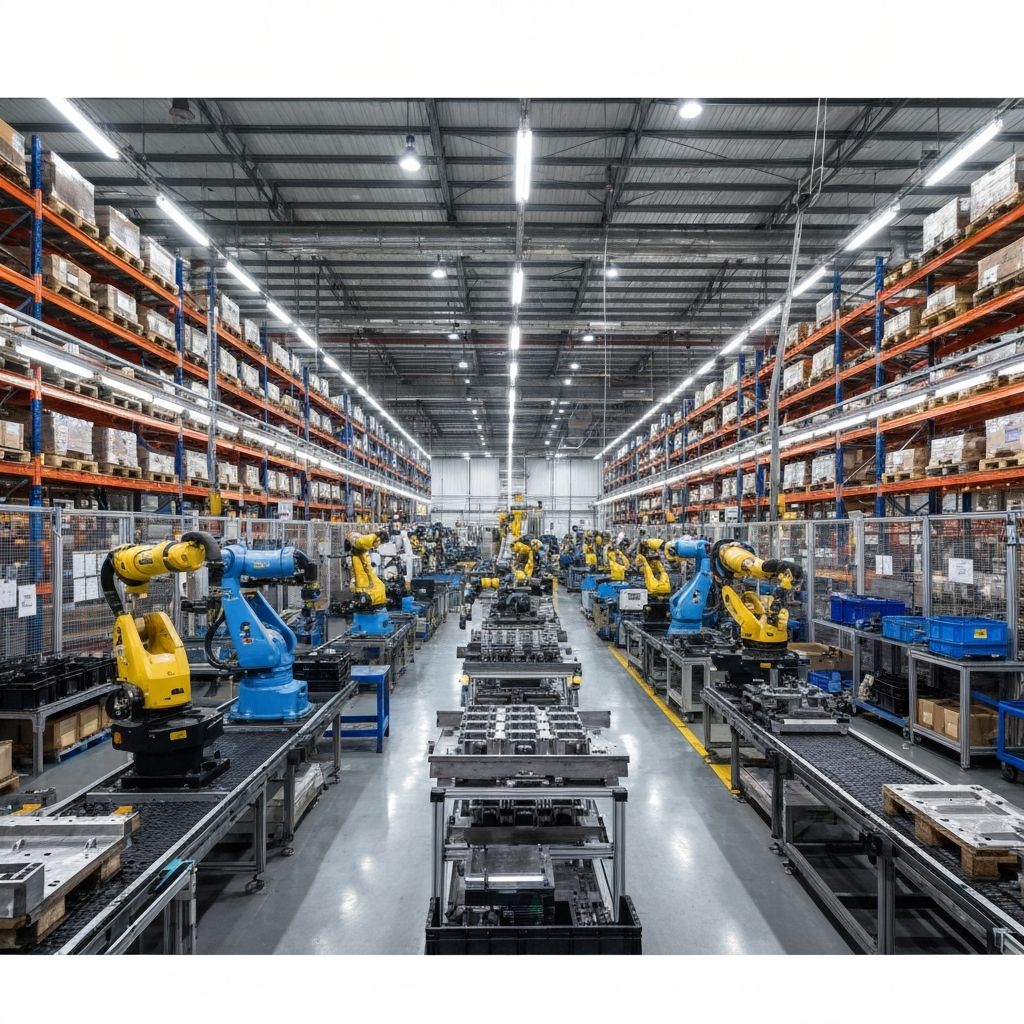

With full predictive maintenance and autonomous anomaly detection services

Why Industry Leaders Choose Omniwatch

Enterprise-Grade Security & Reliability

The Cost of Reactive Monitoring

Traditional monitoring systems alert you after problems occur. By then, it's too late.

Unplanned Downtime

- • $50 billion in annual losses

- • $260,000 per hour of downtime

- • Cascading production delays

Alert Fatigue

- • 80% of alerts ignored

- • Critical issues get missed

- • Team burnout increases

Wasted Resources

- • 60% of time on false positives

- • Reactive instead of preventive

- • Lost productivity daily

Omniwatch Stops Problems Before They Start

Five specialized AI agents work together to detect, explain, prioritize, and solve issues automatically

Catches What Humans Miss

- • 99.3% detection accuracy

- • Analyzes millions of data points

- • Finds invisible patterns

Speaks Your Language

- • Plain-English explanations

- • No cryptic error codes

- • Context-aware insights

Focuses on What Matters

- • Intelligent prioritization

- • Eliminates alert fatigue

- • Only critical notifications

Tells You Exactly What to Do

- • Step-by-step action plans

- • No guesswork required

- • Clear resolution paths

Gets Smarter Every Week

- • Automated retraining

- • Learns your operations

- • Improving accuracy constantly

Zero Human Effort

- • Set it and forget it

- • 24/7 operation

- • Focus on strategy, not fires

Real Results, Real Impact

Companies using Omniwatch transform their operations from reactive to predictive

Predict Equipment Failures

Know exactly when a machine will fail—days or weeks in advance.

- • Schedule maintenance during planned downtime

- • Avoid emergency shutdowns

- • Minimize production disruption

Maintain Perfect Quality

Catch production defects in real-time, before bad products reach customers.

- • Sub-second detection speed

- • Zero compromises on quality

- • Protect your brand reputation

Cut Energy Waste

Identify inefficiencies and optimize consumption patterns automatically.

- • Real-time consumption tracking

- • Automated optimization

- • Immediate bottom-line impact

Scale Without Limits

Monitor 10 sensors or 10,000—Omniwatch scales automatically.

- • Add new equipment instantly

- • No additional complexity

- • Consistent performance at scale

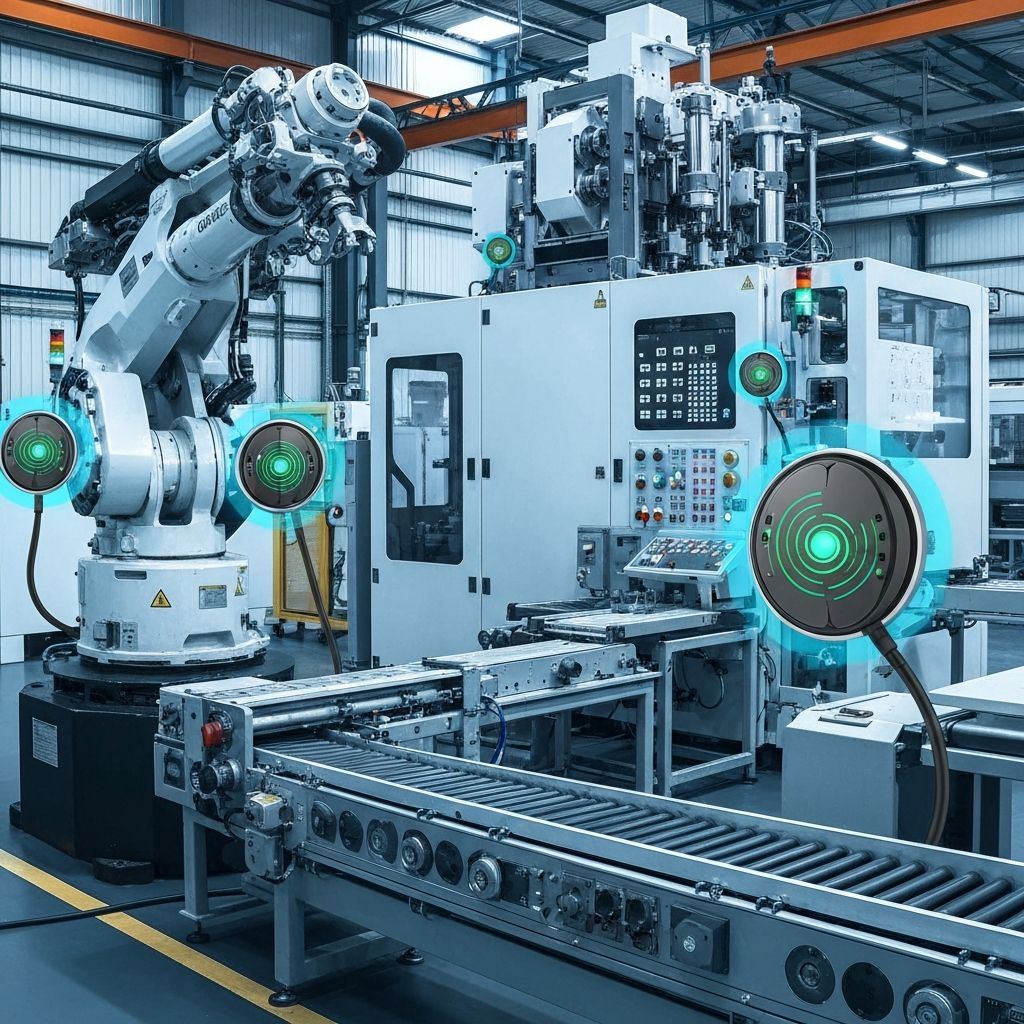

See Explainable AI in Action

Our Glass Box AI shows exactly why it makes decisions, building trust through transparency.

Anomaly Detection in Action

Predictive Maintenance Forecast

Join Industry Leaders

Manufacturing, energy, and logistics companies trust Omniwatch to protect their operations

ROI in the first year for most customers. Savings from prevented failures alone cover the cost.

Average time to full deployment. No months-long implementations. Start seeing value in days.

Compatible with existing sensors and infrastructure. Works with what you already have.

Stop Reacting. Start Predicting.

See how Omniwatch can transform your industrial operations. Start your free 30-day trial—no credit card required.

30-day free trial • Setup in 72 hours • Cancel anytime

Help Us Understand Your Needs

Share your feedback to help us serve you better